To define detail, scope and purpose.

To establish the developed detail in a viewable format to facilitate information.

To facilitate the application of the documentation.

Downloading a resource will add this resource to your resource subscriptions. You will be notified of future updates to this resource via email (you may unsubscribe at any time by clicking the unsubscribe link in the email notification, or to unsubscribe immediately from all update notifications, click here)

Downloading a resource will add this resource to your resource subscriptions. You will be notified of future updates to this resource via email (you may unsubscribe at any time by clicking the unsubscribe link in the email notification, or to unsubscribe immediately from all update notifications, click here)

This information can be used to develop food safety and quality programs that meet the requirements of modern Regulatory, Customer and Industry Standards:

When considering the development, documentation, and implementation of Cleaning and Sanitation within food safety and quality management systems, the following information should be considered to ensure effective outcomes:

Cleaning and Sanitizing programs are an integral part of any food business, providing support for the food safety and quality management system through an established presence within all areas of the premises and surroundings. Cleaning and Sanitation programs should be continually monitored and recorded to ensure their suitability and effectiveness.

The importance of proper cleaning can be appreciated when one realizes that contaminated equipment is historically a major cause of food-borne disease outbreaks. Cleaning and sanitation include many individual and complementary operations in every food premises. Cleaning procedures are commonly specific to the type of cleaning necessary. The priority for Cleaning and Sanitation tasks within any food business is for food contact surfaces, premises, equipment, and utensils.

The goals of Cleaning and Sanitation are to:

Appropriate Cleaning and Sanitizing procedures, in their planning and application, will reduce the risk of cross-contamination of product or process.

Factors in the ability of Cleaning and Sanitation applications to reduce cross-contamination include

Documented cleaning and sanitation procedures need to be in place to monitor and control related issues. This documentation must outline the boundaries that need to be addressed in ensuring safe and quality food production. Cleaning and sanitation procedures need to be developed, documented, and implemented for all areas of consequence to food safety and quality.

Where written cleaning schedules and procedures are used, they should specify:

Where appropriate, Cleaning and Sanitation programs should be formatted in consultation with relevant specialist expert advisors, including your Cleaning and Sanitation chemical suppliers where applicable.

There are many cleaning and sanitation-related tasks which need to be delegated to specific staff within any food business operation.

The following gives us an indication for consideration of cleaning and sanitizing tasks within a food business:

All food handlers may be responsible for the day-to-day cleanliness of the food processing areas in which they work. They may also be responsible for communication with the housekeeping department whenever specific cleaning is required or urgent issues arise.

Food Handler Cleaning and Sanitation duties may include:

Housekeeping and Cleaning and Sanitation staff are generally employed to carry out general and specific housekeeping duties relating to Cleaning and Sanitation among other tasks.

Housekeeping and Cleaning and Sanitation Staff duties may include:

The following section provides an example of commonly applied Cleaning and Sanitation, commonly known as Wet Cleaning:

Cleaned and sanitised equipment and utensils must be:

The use of chemicals within any food business must include elements that not only promote food safety but which also promote the general safe use, handling, and storage of all cleaning, sanitation, pest control, maintenance, and other chemicals. This can generally be facilitated by ensuring documented procedures for chemical control are documented and available to everyone using chemicals.

Chemical usage procedures may include:

All pesticides, sanitizers, cleaners, polishes, lubricants, and other toxic and non-toxic chemicals used in the food business must be:

Food business chemicals must be approved for use in the food establishment. Some products, such as food-grade lubricants, may contain statements by the manufacturer as being approved for use within the food industry or a specific industry sector. Before use within a food business, a confirmation must be received that chemical products are approved for a specific use, and will not potentially contaminate foods. It is important to consider that chemicals such as restricted-use pesticides can only be used by a certified pest control operator. Regulatory approvals may also be required for the use of some chemicals within food businesses.

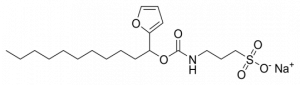

There are many different types of Cleaning and Sanitation chemicals available for use within the food industry.

Detergents are used to remove dirt particles; they are not designed to kill microorganisms, although their pH levels can affect growth and status. Detergents are chemicals that usually have a surfactant quality, making the removal of dirt from surfaces easier. The most appropriate time to clean surfaces with detergents in solution or as recommended is immediately after use, removing food particles before they become hardened and more difficult to remove and facilitate micro-organism growth. The strength of a detergent regarding its cleaning power is reflected in its alkalinity content. It is important to recognize that the use of hot water as a component of cleaning and sanitizing routines where appropriate can dramatically improve the capability of the system to control microorganisms.

Sanitizers are generally not good at removing dirt but do kill microorganisms if used according to the conditions of use. The majority of food poisoning bacteria are killed if they are exposed to heat, chemical sanitizers, or a combination of both. Chlorine or Bleach is one of the most commonly used chemical sanitizers used in food industries today. Commercial bleach typically contains around 10% Chlorine, while the domestic variety is commonly around 4% Chlorine. High-risk areas to be sanitized should use a solution at a concentration of up to 100 parts per million of available chlorine. Other areas and applications may require a solution of around 50 parts per million.

The pH and hardness of the water being used must be determined. Should the water supply be from a municipal supply, the water company may adjust the hardness of the water through processing controls. If the water is from other sources, it may need to be tested periodically to ensure ongoing appropriate outcomes.

Chemical sanitizing generally requires greater controls than sanitizing with hot water or steam.

The following factors must be considered to obtain effective sanitation by chemical methods:

The factors that determine the performance of a particular detergent or sanitizer include:

When not using an automated chemical dosing system, chemical sanitizer instructions call for a given amount of chemical sanitizer per liter of water. This ratio of chemical sanitizer to water is important to ensure ongoing appropriate outcomes for the sanitation process.

If manual chemical sanitizer measuring and mixing methods are used, the processes involved must follow procedure and are verified on an ongoing basis.

Staff involved in applications where they are required to manually measure and mix chemicals must be trained and deemed competent in the required tasks.

Food contact surfaces of equipment and utensils are the surfaces with which food is normally and expected to come into contact. The effective Cleaning and Sanitation of food contact surfaces including equipment and utensils serve two primary purposes:

Although we all know about the practice of ware washing, many do not understand or appreciate the principles of the process, or the outcomes where Cleaning and Sanitation are not completed as required. For the most part, chemistry plays a very important part in the cleaning and sanitizing process. Washing equipment and utensils until visibly clean are just not enough to guarantee outcomes that facilitate the production of safe quality foods.

The most common methods used in cleaning and sanitizing include:

It is highly recommended that specified procedures be followed during Cleaning and Sanitation as part of any effective food safety and quality system.

Where bulk water and food transport vehicles are required to undergo Cleaning and Sanitation, the procedure should generally be similar to that used for food processing equipment commensurate with the materials previously carried by the transport vehicle.

Food processing equipment that requires in-place cleaning should be designed and constructed so that:

Equipment used in production-line food processing should undergo Cleaning and Sanitation according to the following schedules as applicable to the defined risk levels involved:

The following logical sequence is an example of a basic automated ware washing procedure:

The following logical sequences are examples of basic manual ware washing procedures:

Three compartment sink method using hot water sanitizing:

Three compartment sink method using chemical sanitizing:

The following points should be considered within the scope of application for any Cleaning and Sanitation activity:

If your food business supplies foodstuffs manufactured to a customer’s specifications, it is important to consider any specific Cleaning and Sanitation Development requirements in relation to their items.

Document: A document provides guidance and/or direction for performing work, making decisions, or rendering judgments that affect the safety or quality of the products or services that customers receive.

Documented policies, procedures, work instructions, and schedules form the basis of any food safety and quality management system. The following documentation formats may be considered to ensure ongoing compliance with specified requirements for Cleaning and Sanitation:

If your food business supplies foodstuffs manufactured to a customer’s specifications, it is important to consider any specific Cleaning and Sanitation Documentation requirements in relation to their items.

You may wish to visit the Cleaning and Sanitation Templates section of haccp.com for examples of Cleaning and Sanitation documentation, record, and resource formats commonly applied within food safety and quality systems.

Implementation: Implementation is the application of documented food safety and quality system elements into the actual business operation.

The implementation of Cleaning and Sanitation within any food business requires genuine commitment from senior management, staff, and visitors to ensure the nominated goals of implementation are achievable on an ongoing basis. It is a step that requires significant planning and consideration of general and specific food business circumstances to ensure the outcomes of Cleaning and Sanitation do not negatively impact the safety and quality of the food items dispatched from the business.

Implementation of Cleaning and Sanitation must include a clear definition of responsibilities and authorities for all levels of participation by senior management, staff, and visitors to the site.

When implementing Cleaning and Sanitation within a food safety and quality system, you may wish to consider the following requirements before completion:

If your food business supplies foodstuffs manufactured to a customer’s specifications, it is important to consider any specific Cleaning and Sanitation Implementation requirements in relation to their items.

Cleaning and Sanitation Implementation Key Points

Monitoring: Monitoring is the act of reviewing and confirming measurable parameters of a defined process or product status.

Monitoring requirements within food industry sectors are generally identified against limits of acceptability defined within HACCP plans, implementation procedures, and work instructions. Monitoring usually includes some element of record-keeping, which may be maintained manually or through digital systems. It is important to consider that advancements in technology have spawned many systems and processes which are self-monitored and or self-adjusted when variances are identified. Regardless of the system used; The goal of any monitoring activity is to provide sufficient evidence that any limit of acceptability has been met.

Traditional Cleaning and Sanitation monitoring requirements include manual recording and the application of corrective actions when the results of monitoring are found to be outside acceptable limits. Corrective Actions should also generally be strongly linked to the monitoring process where applied to ensure full traceability of the applied actions.

The following examples of monitoring activities and record formats may apply to Cleaning and Sanitation:

If your food business supplies foodstuffs manufactured to a customer’s specifications, it is important to consider any specific Cleaning and Sanitation Monitoring requirements in relation to their items.

You may wish to visit the Cleaning and Sanitation Templates section of haccp.com for examples of Cleaning and Sanitation documentation, record, and resource formats commonly applied within food safety and quality systems.

Corrective Action: Corrective action is mandatory action to be taken when a deviation to the Quality System occurs, particularly in relation to a Critical Control Point.

Preventative Action: At any step in the process where a hazard has been identified, preventive action must be put into place to prevent re-occurrence.

Corrective Action and Preventative Action is implemented to ensure that any identified non-conformance issues are documented, investigated and rectified within appropriate time-frames.pan Corrective action is any action applied to regain control over a product, process, policy or procedure that has been identified as being non-conforming or outside nominated limits of acceptability. Preventative action is any action applied to prevent any identified non-conformance from reoccurring.

The outcomes of corrective and preventative actions should result in regained process control after effective application. Specified corrective actions are commonly linked to the HACCP Plans and to the food business certification process.

Below are Corrective Action and Preventative Action examples which may be associated with Cleaning and Sanitation related non-conformance:

If your food business supplies foodstuffs manufactured to a customer’s specifications, it is important to consider any specific Cleaning and Sanitation Corrective Action requirements in relation to their items.

You may wish to visit the Corrective Action and Preventative Action section of haccp.com for examples of best practice applications for this food safety and quality system element.

Verification: The act of reviewing, inspecting, testing, checking, auditing, or otherwise establishing and documenting whether items, processes, services, or documents conform to specified requirements.

Verification is the detailed review of all food safety and quality system elements to confirm that they are effectively developed, documented, implemented, monitored, and reviewed. All food safety and quality system elements, including documented policies, procedures, training, HACCP plans, and their operational applications must be verified on an ongoing scheduled basis. The verification process commonly includes a defined schedule for which verification activities are required, how often they are conducted, who is responsible, and detailed documented procedures for each nominated verification activity.

The general goal of an established verification process is to ensure any systemic non-conformance issues are identified and rectified within an appropriate time frame. When non-conformance issues are identified through the verification process, Corrective Actions and Preventative Actions should be implemented to ensure they do not impact the effectiveness of the food safety and quality system.

The following examples of verification activities may apply to Cleaning and Sanitation:

Determining if equipment, utensils, and the premises have undergone effective Cleaning and Sanitation can be done through a variety of methods including:

If your food business supplies foodstuffs manufactured to a customer’s specifications, it is important to consider any specific Cleaning and Sanitation Verification requirements in relation to their items.

You may wish to visit the Verification Activities section of haccp.com for examples of best practice applications for this food safety and quality system element.

Validation: The process of gathering evidence to provide a scientific basis for the documented act of demonstrating that a procedure, process, and activity will consistently lead to the expected results. It often includes the qualification of systems and equipment.

Validation is the provision of evidence to support the limits of control or acceptability for food safety or quality parameters nominated within systemic elements. Limits of control or acceptability are commonly included within documented food safety and quality systems elements such as procedures, HACCP plans, and specifications.

Common sources of validation include regulatory and legislative standards, finished product specifications and customer requirements, industry codes of practice and guidelines, verified and validated research, historical product, and process control outcomes, and analytical testing.

The general goal of an established validation process is to ensure any inappropriate limits of control or acceptability are identified and rectified within an appropriate time frame. When non-conformance issues are identified through the validation process, Corrective Actions and Preventative Actions should be implemented to ensure they do not impact the effectiveness of the food safety and quality system.

Validation activities are commonly defined within the verification schedules and procedures of established food safety and quality management systems.

The following examples may apply to validation of the limits of control or acceptability for Cleaning and Sanitation:

If your food business supplies foodstuffs manufactured to a customer’s specifications, it is important to consider any specific Cleaning and Sanitation Validation requirements in relation to their items.

You may wish to visit the Validation Activities section of haccp.com for examples of best practice applications for this food safety and quality system element.

Skills and Knowledge: Skills and knowledge are attributes of human interactions commonly linked to competency within any specific job-related task.

Training and competency requirements for Cleaning and Sanitation must be ongoing, including regular scheduled reviews to ensure the effectiveness of training and competency outcomes.

Team members who have defined responsibilities regarding Cleaning and Sanitation should have knowledge including:

Team members who have defined responsibilities regarding Cleaning and Sanitation should have skills including:

Team members who have defined responsibilities regarding Cleaning and Sanitation should have access to resources including:

If your food business supplies foodstuffs manufactured to a customer’s specifications, it is important to consider any specific Cleaning and Sanitation Training, Competency, and Resources requirements in relation to their items.

You may wish to visit the Training, Competency, and Resources section of haccp.com for examples of best practice applications for this food safety and quality system element.